PVC as a Technical Material: Properties, Advantages and Industrial Applications

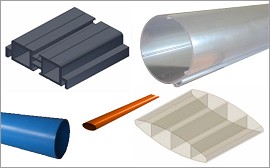

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastic polymers in industry. Its versatility, durability and mechanical performance make it indispensable for the manufacture of tubes, profiles, cores and technical sheaths. Available in both rigid and flexible grades, PVC meets the requirements of many industries, including construction, automotive, signage, packaging and medical.

PVC – an essential industrial material

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastic polymers in industry. Its versatility, durability and mechanical performance make it indispensable for the manufacture of tubes, profiles, cores and technical sheaths. Available in both rigid and flexible grades, PVC meets the requirements of many industries, including construction, automotive, signage, packaging and medical.

At ABI Profils, we specialise in PVC plastic extrusion and provide tailor-made solutions designed to meet the most demanding specifications.

Need advice? Contact our team on +33 (0)4 71 61 29 99 or via our online form.

PVC: outstanding technical properties

PVC owes its popularity to its wide range of technical advantages. Depending on the formulation, it can be rigid or flexible, offering solutions for different environments.

1. Excellent mechanical strength

Rigid PVC is valued for its robustness and dimensional stability. It withstands compression effectively, making it ideal for technical film cores or industrial tubing.

2. Chemical and weather resistance

A major advantage of PVC is its resistance to chemicals, UV rays and weathering. It maintains its properties even after prolonged outdoor exposure.

3. Durability and cost efficiency

PVC is easy to process, cost-effective and combines performance with an excellent price-to-performance ratio.

4. Insulating properties

PVC also provides excellent electrical and thermal insulation, making it widely used in construction, electronics and lighting.

Rigid PVC and flexible PVC: two solutions for different needs

At ABI Profils, we use a variety of PVC formulations tailored to specific industrial requirements.

-

Rigid PVC: strong and stable, ideal for technical profiles, industrial cores and high-strength tubing.

-

Flexible PVC: elastic, suitable for plastic strips, protective sheaths or certain medical applications.

Key industrial applications of PVC

PVC is a material widely used across many industrial sectors. Thanks to its flexibility and durability, it adapts to a wide range of environments.

1. Construction and building

PVC is widely used in construction due to its weather resistance and insulation properties. Applications include sealing profiles, plumbing pipes, ventilation systems and architectural components.

2. Automotive and transport

Both rigid and flexible PVC are used in the automotive sector: cable protection, seat coverings, interior trim. Its shock resistance and tolerance to temperature variations make it reliable for demanding environments.

3. Point of sale (POS) and signage

Transparent PVC tubes and profiles are key components in the production of displays, advertising supports and mounting systems.

4. Medical and paramedical industries

Flexible PVC is widely used in medical applications requiring chemical resistance and hygiene, such as protective sheaths and fluid transport tubing.

5. Packaging and logistics

Lightweight yet strong, PVC is used for plastic cores, storage tubes and protective sleeves in industrial packaging.

6. Lighting and signage

Crystal-clear PVC tubes are often used in LED lighting systems, ensuring uniform light diffusion and providing mechanical protection.

Manufacturing process and quality control at ABI Profils

Our PVC products are manufactured through plastic extrusion, ensuring optimised and consistent production.

-

15 extrusion lines (single and twin-screw) for high-capacity manufacturing.

-

Co-extrusion and post-extrusion technologies for combining materials (rigid/flexible, transparent/opaque).

-

Custom finishing: cutting, punching, inkjet marking, bespoke options.

-

Strict quality control: every product is tested for dimensional stability and durability.

With this expertise, we deliver PVC tubes, profiles and sheaths for the most demanding industries (construction, medical, transport, aerospace) with reproducible quality and high reliability.

Looking for a PVC extrusion expert?

Contact us today on +33 (0)4 71 61 29 99 or via our online form for tailored support.

FAQ – Extrusion and manufacturing of PVC tubes and profiles

What is the difference between rigid and flexible PVC in extrusion?

Rigid PVC is used for tubes and profiles requiring dimensional stability and mechanical strength. Flexible PVC, being more elastic, is used for sheaths, plastic strips and certain medical components.

What dimensional tolerances are possible for extruded PVC profiles?

Tolerances depend on geometry and production conditions. At ABI Profils, we manufacture according to NFT 58000 – Normal Class, which defines dimensional accuracy and repeatability, while allowing adjustments to customer specifications.

What types of finishing can be applied to extruded PVC tubes or profiles?

Beyond extrusion, finishing options include cutting (straight or angled), drilling, punching, threading, inkjet marking for traceability, and adhesive application. These operations are carried out inline or post-extrusion to optimise lead times.

Is extruded PVC resistant to UV and chemicals?

Yes, certain PVC formulations are stabilised to resist UV radiation, weathering and aggressive chemicals, making them suitable for outdoor and industrial use.

Back to news home page

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands