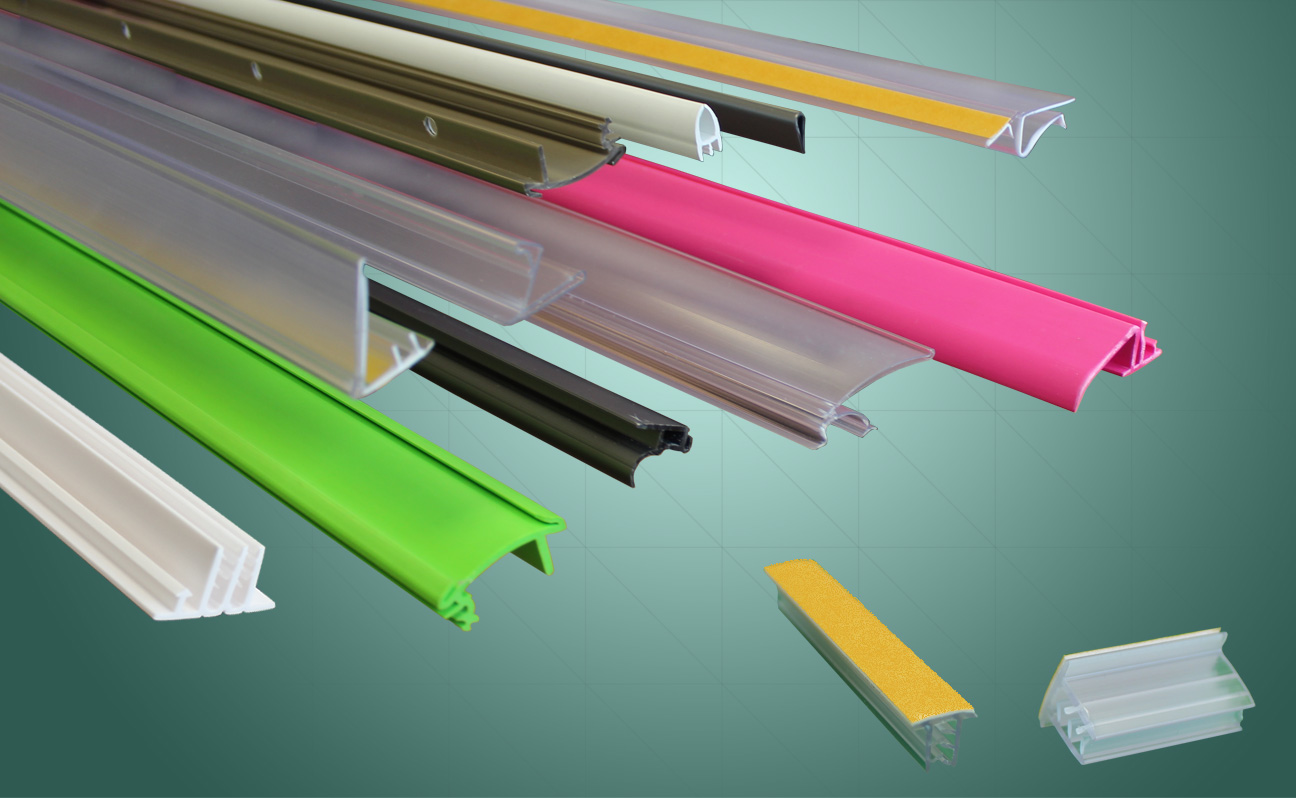

Technical plastic profiles

Our company’s know-how can be seen on a daily basis in the development and manufacturing of standard and specific profiles.

We offer a wide range of single or multi-material plastic profiles for different applications in the automotive, construction, para-medical industries, also for dynamic storage, point of sale display, DIY, sports & leisure, packaging as well as many others.

Our development skills associated with high performance production tools mean we are able to offer a diverse range of technical products :

- Tubular or single wall plastic profiles

- Multi material and multi colour plastic profiles

- Two component (coextruded) plastic profiles

- Single and two material (coextruded) plastic profiles

- Single and two colour plastic profiles (coextrusion)

- Opaque or transparent plastic profiles

- Flexible or rigid plastic profiles

- Very thick or very thin plastic profiles

- Plastic profiles with optional finishing operations

- Semi finished products (mounting & assembly)

- Label holder, poster clip, point of sales display profiles, etc

With clearly defined quality objectives having a single goal : to satisfy our customers’ needs.

ABI Profils : The know-how for your innovation !

What are the specific properties of our plastic profiles?

Various materials can be used for plastic profiles. Thermoplastics, such as polycarbonate and polyamide, or bulk plastics, such as PE and PVC, are particularly common. The type of material will be determined by your needs. Each plastic has specific properties that make it suitable for its area of application. Our range of materials includes PVC, PP, PP FV, PE, PMMA, SEBS, PC, PA, PA FV, ABS, PS, PETG, ASA, TPV, TPU and many others.

For example, if the profiles have to be rigid, the material used will be a thermoplastic such as PVC, PAFV, ABS, PC… If the requirements are for good plasticity, the material used will be a thermoplastic such as Soft PVC, SEBS or HDPE. Compared with profiles made from other materials, plastic profiles offer a number of advantages and are often used for the reasons set out below. Here are the main advantages of ABI Profils plastic profiles.

Plastic profiles have :

- excellent strength

- very good elasticity

- very good durability

- very good abrasion resistance

- very good impact resistance

- high UV resistance

- high durability, including resistance to weathering

- thermal and electrical insulation properties

- so they can be used both indoors and outdoors.

The material is selected according to your specifications (characteristics, functions, etc.) and requirements. Our design office and project managers work together to offer you the technical solution best suited to your needs.

Plastic profiles can be used in many fields

Plastic profiles can be found in a wide range of applications, including the automotive industry, construction, dynamic storage, paramedical, packaging, POS, sports and leisure, and aeronautics.

Examples of plastic profiles by sector

- For the automotive industry: We produce trim profiles, bi-component textile profiles, safety reinforcement profiles, various plastic profiles, etc.

- For the building industry: We manufacture waterproofing profiles, cladding profiles, etc.

- For dynamic storage: We manufacture structural profiles, protection profiles, ESD profiles, cladding profiles, etc.

- For the paramedical sector: We produce profiles for everything from hospital protection to care…

- POP, packaging and aeronautics: We produce profiles for packaging and displays.

Thanks to the various manufacturing processes described below, our profiles are versatile. It is possible to produce single pieces, in medium or large series. Production is carried out entirely according to your specifications, and we can also adapt to specific requests. Please note that the plastic profiles we extrude are also suitable for the electronics, food, DIY and mechanical engineering industries.

Find out more about all the applications for our plastic profiles

Our plastic profiles are produced by plastic extrusion

Extrusion is the most common manufacturing process for plastic profiles. The material is first melted, then homogenised using an endless screw and finally pressed through an extruder. The plastic used is determined by your specifications. We are moving towards a 4.0 manufacturing plant with cutting-edge technologies, and are equipped with 15 single- and twin-screw extrusion lines, giving us the versatility to meet all your requirements. As a result, our plastic profiles are of the highest quality and have a long service life.

Click here to find out more about plastic extrusion and our production facilities.

Buy plastic profiles from ABI Profils

ABI Profils has over 40 years’ experience in the manufacture of plastic profiles. We manufacture technical profiles in a variety of plastics to suit your needs. This means that our customers benefit from optimum economic and technical solutions to ensure that their requirements are 100% satisfied. We work with you to develop an individual solution. This is precisely tailored to your requirements.

Production is carried out using state-of-the-art technology and is adapted to the plastics and their processing, while preserving resources and the environment.

We offer a wide range of plastic materials, from the most standard to the most technical, including regenerated materials. Tools are designed using a 3D and 2D CAD system in our own workshop. In order to follow the different stages of your development, we use a Product Development File (called “PDF” in English or “FDP” in French). A functional and aesthetic analysis will focus on manufacturing feasibility. But also on the cost of industrialisation. These documents will of course be sent to you when you open the file. They will include all the different guidelines for your project.

Taking into account your specifications and your technical, functional, aesthetic and environmental constraints, a project manager will guide you through all the phases of your development.

The different stages in the development of your plastic profiles

Here’s an outline of the different stages in the development of your plastic profiles:

- Product Development Sheet Design and modelling ( 3D / 2D ) / Drawing up

- Design and modelling ( 3D / 2D ) / Layout

- Creation and anticipation of the project schedule

- Preparation of the Product Quality Analysis File : DAQP

- Provision of our materials analysis and product prototyping service

- Technical study and production of dies and process tools

ABI Profils services are available throughout the process: from specifications to industrialisation.

Find out more about our design office here

Contact us

At ABI Profiles, every project is unique. That’s why it’s important for us to meet you for an initial face-to-face or remote discussion to define the best solutions to your problems. Our guiding principle is to create optimum solutions for your standard and specific plastic profiles. We’ve been experts in this field for over 40 years.

Our team is ready to advise you. Under the leadership of Lionel CHANTEGRAILLE, CEO of ABI Profils, there is a whole network of people ready to respond quickly to your needs. Don’t hesitate to leave us a message using the contact form or call us on +33 4 71 61 29 99

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands