QUALITY - INNOVATION - PROCESS

-

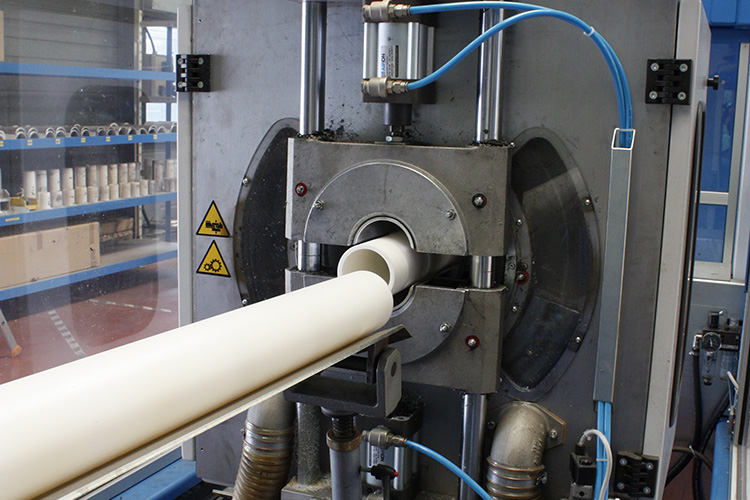

Definition of extrusion : The extrusion of plastic is the process whereby plastic material is pushed through a die

Plastic extrusion is obtained with an extruder that softens the plastic material with heat; it then carries the molten material through the machine with the main element of an extruder, the screw, the molten plastic then goes through the die. After this operation the hot product must be cooled as quickly as possible in order to obtain the correct dimensional characteristics of the profile that correspond to customer specifications. This production stage is known as calibration.

-

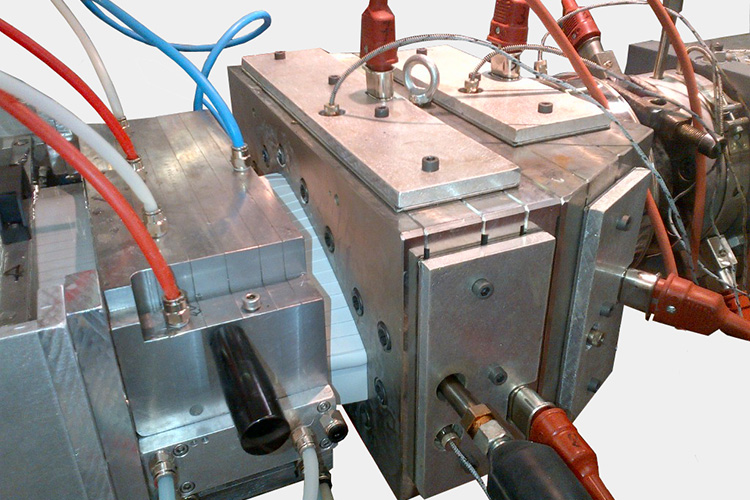

Definition of coextrusion : Coextrusion is the process whereby several plastic materials are pushed through a die

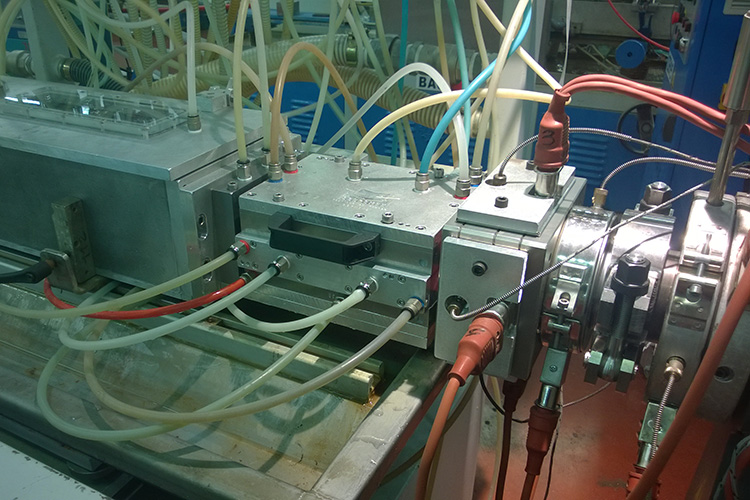

In coextrusion two plastic or polymer materials are brought together by chemical bonding. Two extruders with two hoppers feeding different materials into a special die head are necessary for this type of process which means parts with two different materials can be manufactured; rigid and flexible or with two colours. This process is generally used with the objective of creating dual functions required by the product specifications, for example for a clip (rigid material) that is waterproof (flexible material). The profile is then calibrated and cooled in the same way as in the extrusion process.

Our know-how working for your innovation … to ensure the best performance, our factory teams are organised into three shifts and work with the following production tools :

- 14 WEBER – AMUT – BATTENFELD CINCINNATI single and double screw plastic extrusion lines

- 6 two material coextruders

- A tooling warehouse with 300 standard references (tubes & profiles)

- Adaptable, adjustable and evolving equipment on our production lines (cutting, straight cutting, diagonal cutting, stamping, ink jet marking, in-line glueing, adhesive and magnet mounting…)

- Two and three component feeder devices

- Specific product / process adaptations

- Production capacity from 10g to 5kg per linear metre

- Quality department with ISO 9001 certification

With these continually evolving, high performance tools, we are ready to work with you to satisfy your product and project requirements.

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands