News

PVC as a Technical Material: Properties, Advantages and Industrial Applications

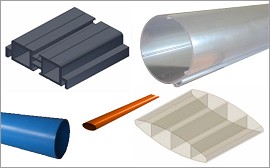

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastic polymers in industry. Its versatility, durability and mechanical performance make it indispensable for the manufacture of tubes, profiles, cores and technical sheaths. Available in both rigid and flexible grades, PVC meets the requirements of many industries, including construction, automotive, signage, packaging and medical.

For more informationPVC Tubes or PP Tubes? Which Performance for Which Application?

Across many industrial sectors – from construction to food processing, transport to chemicals – plastic tubes play a vital role. Among the most commonly used materials, PVC (Polyvinyl Chloride) and PP (Polypropylene) stand out as reference solutions, each with specific properties.

For more informationRigid Transparent Plastic Tubes : Selection Criteria for Industrial Use

Rigid transparent plastic tubes are essential in many industrial sectors. They are widely used in lighting, signage, medical applications and even design. Their transparency and mechanical strength make them indispensable components. But how do you choose the right material? Which characteristics should be prioritised to guarantee performance and durability in demanding environments?

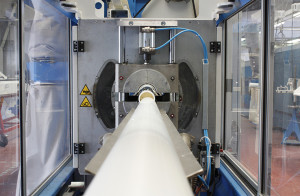

For more informationUnderstanding Plastic Extrusion: Processes, Materials and Industrial Applications

Plastic extrusion is a continuous manufacturing process for thermoplastic polymers. The raw material (granules, powders or resins) is melted and pushed through a calibrated die to create a plastic tube or profile with precise dimensions.

For more information

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands