ANALYSIS - DEVELOPMENT - DESIGN

Design Office Specialising in Plastic Extrusion

For over 40 years, ABI Profils has been supporting manufacturers with the bespoke development of extruded plastic tubes and profiles. Thanks to our in‑house design office, we work with you from the early design stage to ensure feasibility, cost‑effectiveness and reliability throughout the production process.

An Expert Team for End‑to‑End Project Support

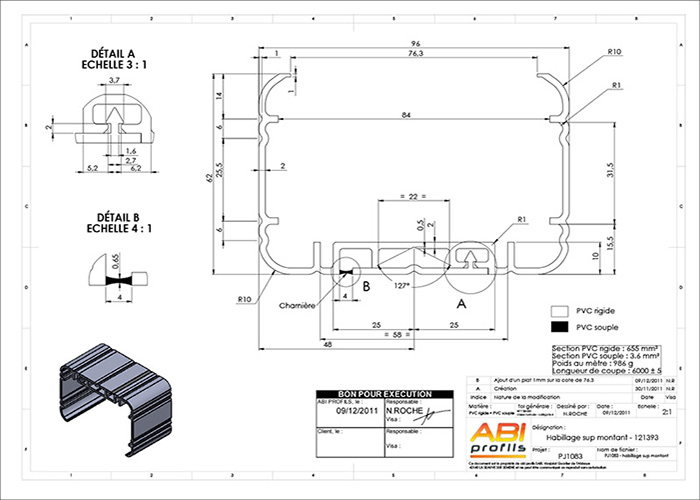

Our R&D department comprises engineers and technicians specialised in plastic extrusion, using advanced CAD/CAE tools (such as SolidWorks and AutoCAD) to design your parts in 2D and 3D.

Our technical approach focuses on:

-

Optimising shapes to suit extrusion constraints

-

Selecting the right material for your chemical, thermal or mechanical requirements

-

Reducing production costs and shortening development times

Development Methodology

Each new project is managed by a dedicated technical lead and structured around a Product Development Specification (PDS), detailing:

-

Functional objectives

-

Geometric and dimensional constraints

-

Regulatory or sector‑specific requirements

We then establish a design timeline and move through the following steps:

Key Stages of Our Process

-

Functional and aesthetic review

-

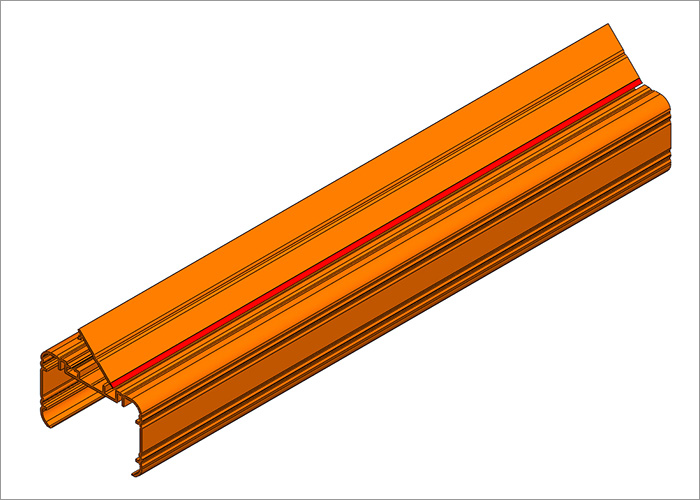

3D part modelling

-

Material studies and simulations

-

Functional rapid prototyping

-

Tooling and die design for extrusion

-

Creation of the Product Quality Analysis File (PQA)

-

Pre‑series validation

Technical Capabilities Integrated into Our Design Office

Our innovative strength lies in integrating advanced technical resources, tailored to the needs of plastic extrusion:

-

A flexible, modular extrusion process

-

Multi‑material co‑extrusion lines

-

Rapid prototyping equipment

-

In‑house tooling design and manufacturing

-

A machine park compatible with technical, recycled and bio‑sourced polymers

For more information about our industrial capabilities, visit our dedicated production facilities page.

Application Areas

Our bespoke developments meet the demands of highly specialised sectors:

-

Construction & Safety: Finishings, connectors, spacers

-

Agri‑food: Tubes and profiles suitable for food contact

-

Automotive: Technical profiles with tight tolerances

-

Medical: Flexible tubing and profiles for controlled‑use applications

-

Industrial Packaging: Strong winding cores, protective sleeves

Technical Benefits of Our Development Support

Integrating our design office into the extrusion process allows you to optimise product performance while guaranteeing reproducibility:

-

Shorter Development Times

A structured approach (PDS, CAD/CAE, validations) allows for quick and reliable fine‑tuning of projects. -

Compliance with Regulations

REACH, RoHS, and food‑contact requirements are considered from the design phase, aligning with your specifications. -

Extended Material Compatibility

PVC, HDPE, LDPE, PET, PETG, PP, ABS, PS, TPV, PC, PA6, SEBS as well as recycled and bio‑sourced formulations. -

Guaranteed Dimensional Stability

Thermal‑mechanical behaviour and material shrinkage are accounted for from the design phase.

Contact Our Plastic Extrusion Design Office

📞 Need technical advice or a feasibility review?

Call us on +33 4 71 61 29 99 or fill out our online contact form. We’re here to transform your ideas into concrete industrial solutions.

ABI Profils : According to your profile!

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands