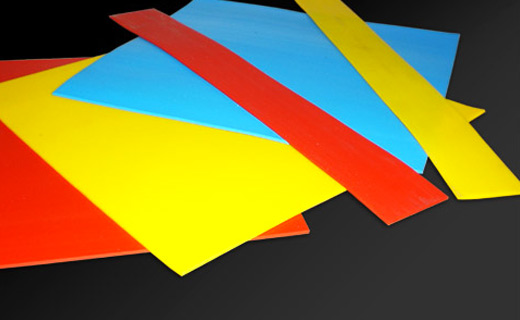

Flexible plastic strips

At ABI Profils, we produce a comprehensive range of flexible plastic strips. These products meet the diverse needs of many application fields. Available in both standard and customised dimensions, our strips offer strength, flexibility, and durability, ensuring optimal performance for every specific application.

Fields of Application

Flexible plastic strips are used in various sectors, including:

- Construction: For insulation or partitioning applications.

- Sports and Leisure: For durable, flexible equipment.

- Signage: For coloured markers and flexible elements.

- Other Industrial Applications: Suitable for specific projects requiring both flexibility and strength.

For more information on our application areas, click here.

Technical Information

- Widths: From 5 mm to 400 mm

- Materials: Flexible PVC and SEBS (all Shore hardness levels)

- Finishes: Transparent or coloured strips

- Packaging: Supplied on coils (metre lengths) or in pre-cut lengths

- Production Volumes: Medium & large production runs

For particular dimensions or characteristics, please contact our team.

Materials Used

Our flexible plastic strips are manufactured using carefully selected materials known for their durability and suppleness:

- Flexible PVC: A versatile material offering excellent flexibility and strong resistance to temperature changes, impacts, and chemicals. It is particularly suitable for industrial environments.

- SEBS: A thermoplastic elastomer combining flexibility and sturdiness, with excellent mechanical resilience and increased resistance to UV, ozone, and external agents. Available in various hardness levels according to application requirements.

These materials ensure high performance even under demanding conditions, providing maximum longevity and adaptability across multiple application sectors.

Manufacturing Process and Quality

Flexible plastic strips are produced through plastic extrusion. This process guarantees homogeneous products that meet the most stringent quality standards. The material is melted, homogenised, and then pushed through an extruder to form the strips.

At ABI Profils, we have 15 single-screw and twin-screw extrusion lines, allowing us to adapt our production capacity to your project specifications.

To learn more about our manufacturing processes, click here.

Purchasing flexible plastic strips from ABI Profils

With over 40 years of experience in manufacturing flexible plastic strips, ABI Profils produces tubes and technical profiles in various plastics according to your needs (from standard to advanced technical materials, including recycled options). We develop a customised solution in collaboration with your teams, precisely tailored to your specific requirements.

Production is carried out exclusively using modern technologies, optimised for plastic processing and preserving both resources and the environment.

Tooling is designed using a 3D/2D CAD/DAO system in our own workshop. To track every stage of your development, we operate under the Product Development Sheet (FDP) method. A functional and aesthetic analysis focuses on manufacturing feasibility as well as industrialisation costs. These documents consolidate all guidelines for your project.

Taking into account your specifications—along with technical, functional, aesthetic, and environmental constraints—a dedicated project manager supports you through all phases of your development.

Contact a project manager for more information or to discuss your project.

Key phases in developing your flexible plastic strips

Below are the main steps for developing your projects at ABI Profils:

- Creation of the Product Development Sheet (FDP)

- 3D/2D design and modelling

- Scheduling the project timeline

- Compiling the Product Quality Analysis Document (DAQP)

- Material analysis and prototyping

- Technical study and tooling production

ABI Profils remains involved throughout the entire process, from your initial specifications to industrialisation.

Contact us

At ABI Profils, every project is unique. That is why we believe it is important to meet you—whether in person or remotely—to identify the best solutions for your requirements. Our guiding principle: creating optimal solutions for your standard and bespoke plastic profiles. We have been experts in this field for over 40 years.

Our team is on hand to provide advice. Under the leadership of Lionel CHANTEGRAILLE, CEO of ABI Profils, a network of collaborators is ready to respond quickly to your requests. Feel free to contact us via our online form or by phone on +33 (0)4 71 61 29 99.

ABI PROFILS: Expertise at the service of your innovation!

Contact us

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands