Understanding Plastic Extrusion: Processes, Materials and Industrial Applications

Plastic extrusion is a continuous manufacturing process for thermoplastic polymers. The raw material (granules, powders or resins) is melted and pushed through a calibrated die to create a plastic tube or profile with precise dimensions.

What is plastic extrusion?

Plastic extrusion is a continuous manufacturing process for thermoplastic polymers. The raw material (granules, powders or resins) is melted and pushed through a calibrated die to create a plastic tube or profile with precise dimensions.

At ABI Profils, we master single-screw and twin-screw extrusion, co-extrusion, and post-extrusion, meeting the most demanding specifications across sectors such as construction, automotive, medical, and aerospace.

The stages of the plastic extrusion process

1. Feeding the raw material

The raw polymer (granules, powder, or resin) is fed into an extruder, a specialised machine equipped with an extrusion screw.

The material enters the hopper via gravimetric or volumetric dosing systems to guarantee consistent formulation.

2. Heating, plasticising and melting

The screw (single or twin) gradually melts the polymer using controlled heating zones to produce a homogeneous, malleable texture.

-

Temperature precisely regulated by multi-point control

-

Homogenisation through compression, dosing and degassing zones to eliminate bubbles and trapped air

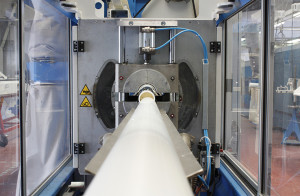

3. Passage through the die

The molten material is forced under pressure through a die that gives the extrudate its final shape.

Our design office optimises each die geometry to ensure stable melt flow and minimise shrinkage effects.

Multi-channel dies can also be manufactured for co-extrusion, combining several materials (rigid/flexible, transparent/opaque, etc.).

4. Cooling, calibration and dimensional stabilisation

As it exits the die, the tube or profile is cooled and shaped using calibrators to guarantee dimensional stability and mechanical consistency (final dimensions are achieved after cooling).

5. Cutting and finishing

Inline or post-extrusion, we provide a complete range of integrated finishing options:

-

Automated straight or angled cuts

-

Drilling, punching, threading according to specifications

-

Inkjet marking for traceability, regulatory compliance, or brand enhancement

-

Application of technical adhesives (TESA, double-sided, repositionable) or magnets

At ABI Profils, finishing is carried out directly at our production site in partnership with a supported employment centre (CAT). This ensures responsiveness, production flexibility and a true made-to-measure service, without external subcontracting.

Extrusion, co-extrusion and post-extrusion: what are the differences?

-

Extrusion: involves a single material.

-

Co-extrusion: combines several polymers within the same profile, enabling properties such as rigidity and flexibility, or transparency and opacity, to be integrated simultaneously.

Advantages of plastic co-extrusion:

-

Rigid/flexible combinations (e.g. rigid PVC + flexible SEBS)

-

Two-colour or dual-material parts

-

Enhanced technical performance (clipping, sealing, durability)

Example: An industrial sealing gasket co-extruded with a rigid base and a flexible lip in SEBS or soft PVC.

Post-extrusion is an alternative to co-extrusion. A first rigid section is extruded and stabilised, then reheated to receive a second section (generally flexible) via a separate die.

Advantages of plastic post-extrusion:

-

Strong adhesion between materials

-

Reinforced dimensional stability

-

Greater design freedom for specific requirements

Example: Profiles for industrial closures — a rigid PVC profile is first extruded, then reheated to integrate a flexible gasket (SEBS or soft PVC) through post-extrusion. This provides structural strength while ensuring airtightness, watertightness, or sound insulation.

Which materials are used in plastic extrusion?

At ABI Profils, we work with a wide range of thermoplastic polymers. Materials are selected based on their technical properties and compatibility with the final application.

| Material | Characteristics | Industrial Applications |

|---|---|---|

| PVC (Polyvinyl Chloride) | Chemical resistance, rigidity, cost-effective | Electrical conduits, technical profiles, sheaths |

| HDPE (High-Density Polyethylene) | Excellent impact and wear resistance | Food industry, chemical storage |

| PP (Polypropylene) | Lightweight, chemical resistance | Packaging, automotive, textiles |

| PA6 (Polyamide 6) | High mechanical and thermal resistance | High-performance parts, aerospace |

| SEBS (Styrene-Ethylene-Butylene-Styrene) | Elasticity and UV resistance | Seals, plastic straps |

Our experts advise you on the most suitable material, considering mechanical, chemical, and thermal requirements.

ABI Profils: expertise and production capacity

Our expertise is based on a high-performance and versatile production facility. We operate 15 single- and twin-screw extrusion lines and 6 co-extrusion machines, enabling us to deliver tailor-made solutions for every industry.

Our production capabilities:

-

Single- and twin-screw extrusion for versatility

-

Plastic co-extrusion for advanced dual-material products

-

Custom plastic tubes and profiles

-

Integrated ISO 9001 quality control

-

Optimised production ensuring repeatability and maximum dimensional accuracy

This expertise allows us to serve industries such as construction, manufacturing, electronics, aerospace, transport, and medical. Discover all our application fields [here].

Looking for a plastic extrusion expert?

Need advice or a quotation? Contact us to discuss your project with our team and discover the right solution for your industry. Use our online contact form or call us directly on +33 (0)4 71 61 29 99.

FAQ – Frequently Asked Questions

What is the difference between extrusion and co-extrusion?

Extrusion shapes a single material, while co-extrusion combines several materials in one product to optimise mechanical and chemical properties.

What is the difference between post-extrusion and co-extrusion?

Both combine multiple materials. Co-extrusion uses a multi-channel die, whereas post-extrusion requires a second, separate die.

What are the advantages of plastic extrusion compared to other processes?

Plastic extrusion is ideal for series production of plastic profiles and tubes with high dimensional accuracy, optimised production costs, and design flexibility.

How do I choose the right material for a plastic extrusion project?

It depends on the mechanical, chemical, and thermal constraints of the final application. Our team will guide you in selecting the most suitable solution.

Back to news home page

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands