Our products

Our materials

| ABS |

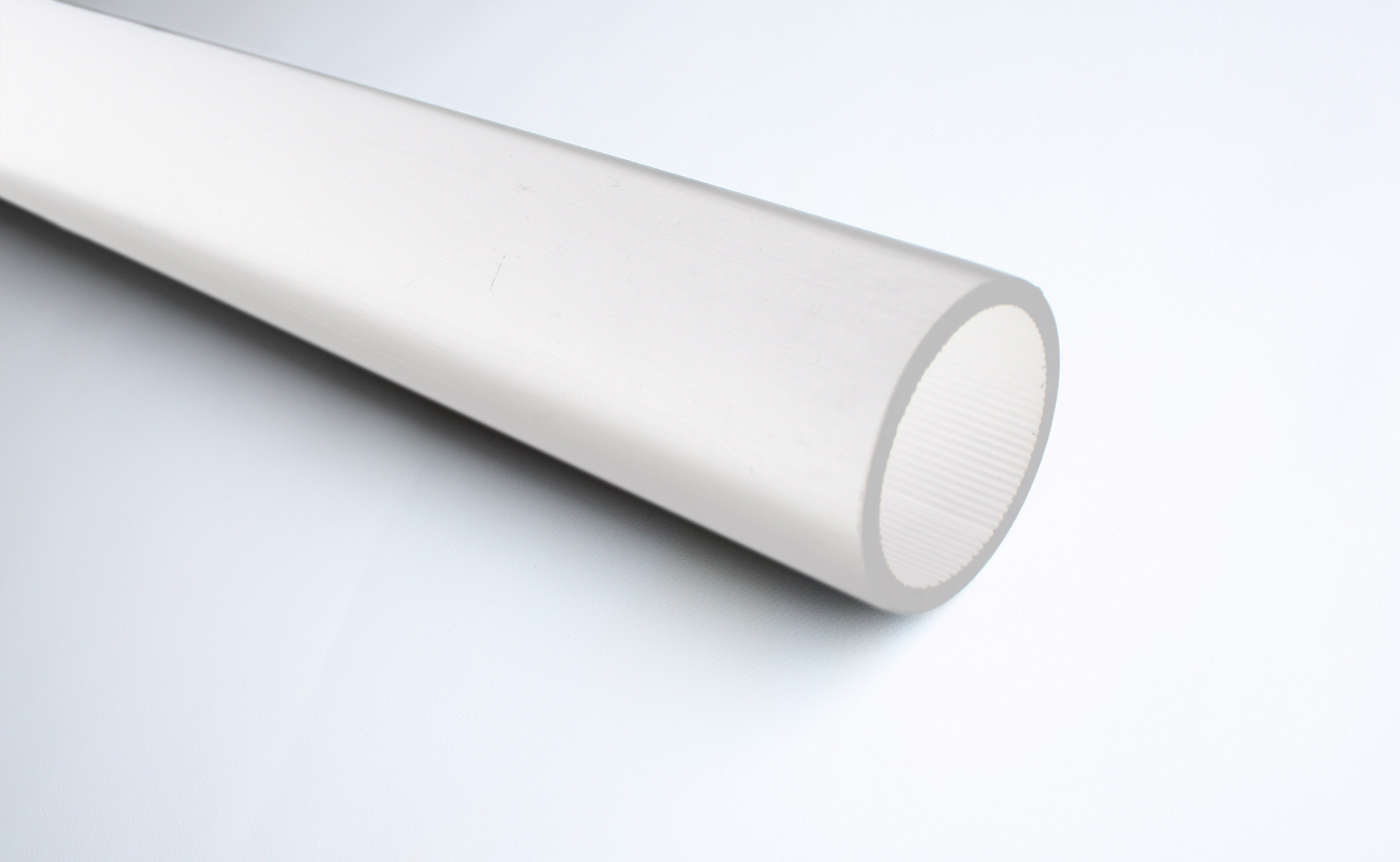

ABS cores

Our ABS (Acrylonitrile Butadiene Styrene) cores are designed to meet high standards of mechanical strength, food safety, and aesthetics. These cores offer excellent impact resistance and temperature stability while reducing dimensional tolerances.

Available in a wide range of standard or custom sizes, they are particularly suited for demanding industrial applications, especially in sanitation and plastic film winding sectors.

Fields of Application

ABS cores are used across various industrial sectors, including:

- Medical and pharmaceutical industries: Thanks to its chemical stability and smooth finish, ABS is a reliable choice for specific applications in these fields.

- Sanitation: For products requiring high mechanical and chemical resistance.

- Plastic film industry: For winding protective plastic films subjected to mechanical and thermal constraints.

- Packaging sector: Ideal for high-end packaging or films needing an aesthetic and robust support.

- Other industrial sectors: Applications requiring high dimensional precision and refined aesthetics.

You can find more details on our fields of application here.

Technical Information

- Internal diameters: Available in most 3-inch sizes: Ø 76 to Ø 102 mm, with other sizes available upon request.

- Internal finish: Smooth or ribbed versions available.

- Widths: Inline cutting from 100 mm to 4000 mm.

- Material: Acrylonitrile Butadiene Styrene (ABS), suitable for demanding environments.

For specific dimensions or unique requirements, contact us!

Material Used

Our cores are made of Acrylonitrile Butadiene Styrene (ABS), a thermoplastic polymer known for its excellent mechanical properties. ABS is particularly valued in industrial environments for the following reasons:

- High impact resistance: Thanks to its polymer structure, ABS offers excellent impact resistance, even under challenging conditions.

- Temperature variation resistance: ABS maintains its dimensional stability in environments subject to significant thermal variations.

- Aesthetic and dimensional precision: ABS enables very tight tolerances, making it ideal for applications requiring high precision.

- Chemical inertia: This material is compatible with environments exposed to aggressive chemical substances, making it well-suited for sectors like sanitation.

- Recyclability: Fully recyclable, ABS is an environmentally responsible choice that supports sustainable material management.

Manufacturing Process and Quality

ABS cores are produced using plastic extrusion. This process ensures uniform products that meet the highest quality standards. The material is melted, homogenised, and shaped through an extruder to form the cores.

At ABI Profils, we operate 15 mono- and twin-screw extrusion lines, allowing us to adjust production capacity to your project specifications.

For more details on our manufacturing processes, click here.

Purchasing ABS Cores from ABI Profils

With over 40 years of experience, ABI Profils specialises in manufacturing ABS cores. We produce technical cores in various plastic materials tailored to your needs, from standard to technical or recycled materials. We collaborate with your teams to develop individual solutions precisely adapted to your requirements.

Production is exclusively carried out using modern technologies, tailored to the materials and their processing, while preserving resources and the environment.

Tool design is performed using 3D and 2D CAD systems in our in-house workshop. To manage development stages, we follow the Product Development Sheet (PDS) method, which includes functional and aesthetic analyses focused on manufacturability and industrialisation costs. These documents outline all guiding principles for your project.

Taking into account your specifications, technical constraints, functional needs, aesthetic requirements, and environmental concerns, a project manager will support you throughout the development process.

Contact a project manager to learn more and discuss your project.

Development Phases for Your ABS Cores

Here are the main steps for developing your projects with ABI Profils:

- Creating the Product Development Sheet (PDS).

- 3D/2D design and modelling.

- Anticipating project timelines.

- Compiling the Product Quality Analysis File (PQAF).

- Material analysis and prototyping.

- Technical study and tool design.

ABI Profils supports you throughout this process, from specifications to industrialisation.

Contact Us

At ABI Profils, every project is unique. That’s why we prioritise meeting you in person or remotely to define the best solutions for your challenges. Our mission: to create optimal solutions for your standard and specific plastic profiles. With over 40 years of expertise, we are ready to assist you.

Our team is at your service. Under the leadership of Lionel CHANTEGRAILLE, CEO of ABI Profils, a network of collaborators is ready to meet your needs quickly. Feel free to contact us via our online form or by phone at +33 4 71 61 29 99.

ABI PROFILS: Expertise at the service of your innovation!

Français

Français Česky

Česky Deutsch

Deutsch Slovenský

Slovenský Belgisch-Nederlands

Belgisch-Nederlands